ERP Methods for SMB Manufacturers

Every manufacturing company needs a system for managing their business end to end - from sales to production to inventory to quality to accounting. Often, SMB manufacturers will start with Excel and Quickbooks, but this will only support their business up to a certain level. At this point, they need to determine how to support and handle growth in a cost-effective manner.

The value of an ERP (enterprise resource planning) software is the ability to unify these departments into one platform that houses the core data and processes a manufacturing business needs to operate successfully. This is the goal of digital transformation: to operate your business more efficiently and accurately, positioning you to have a competitive advantage and adapt to stay relevant for years to come.

One of the unique opportunities ERP consultants enjoy is the interaction with a wide range of different types of companies and their processes. Cetec ERP consultants interface with a large number of manufacturing modes and industries; doing so teaches them how companies operate and which systems best support these businesses. Consultants also learn firsthand how innovation addresses new challenges, whether it be a macro issue like the supply chain disruption during COVID, or a micro issue such as adapting to increased customer requirements.

Determining the right ERP system for a small or mid-sized manufacturer is critical. ERPs are expensive and risky, and there are numerous stories of poor implementations sinking businesses. An SMB manufacturer must carefully sift through the different solutions they come across while seeking to grow their business and consider for implementation. Let’s explore the different ways SMB manufacturers address the challenges and needs for an efficient system capable of running their entire business.

Enterprise-level ERPs

Enterprise-level ERPs are built for large companies that are Fortune 500 or Fortune 1000 oriented. These include SAP, Epicor, and Oracle. Since they are built to run any large businesses with highly complex processes, they are behemoths of software packages requiring a significant amount of customization, configuration, and consulting.

We see these known, name-brand ERPs leveraged by SMB manufacturers because ‘nobody gets fired for buying IBM’. Their massive marketing budgets might make them the easy choice, but not necessarily the right choice. The reality is that these providers are large, inflexible, and disconnected from customer use cases. To them, an SMB manufacturer is a small fish that will get ignored or brushed to the side. The software is bloated and overpriced, and user support is expensive or nonexistent.

A sub-category of these ERPs exists that market specifically to SMB companies. Rather than a nimble, usable solution, these ERPs tend to suffer from the same flaws as the very platforms they seek to replace. They brand themselves as SMB software, but still tend to be rigid, incredibly expensive, and without much personal support.

Typically, the ERPs marketing to SMB companies are stronger on the financial reporting side of things. They will cater well to the CFO, and are useful for staying in compliance with Sarbanes-Oxley (SOX) requirements. However, because they put their focus only on the accounting side of a business, they often miss vital manufacturing management modules entirely.

These systems can be customized to provide shop floor management, or have partnerships and plugins to make manufacturing possible, but are not true manufacturing ERPs. This leaves operations with a clunky system and bigger mess to manage.

There exists, however, a range of solutions that are genuinely catered to SMB manufacturers, rather than a platform designed for another profession or business size that is marketing itself beyond its specialization. Some of these solutions are out-of-the-box, and other solutions are heavily customized. Let’s explore some examples.

SMB Manufacturing Options

Excel/Quickbooks (or QB plug-ins)

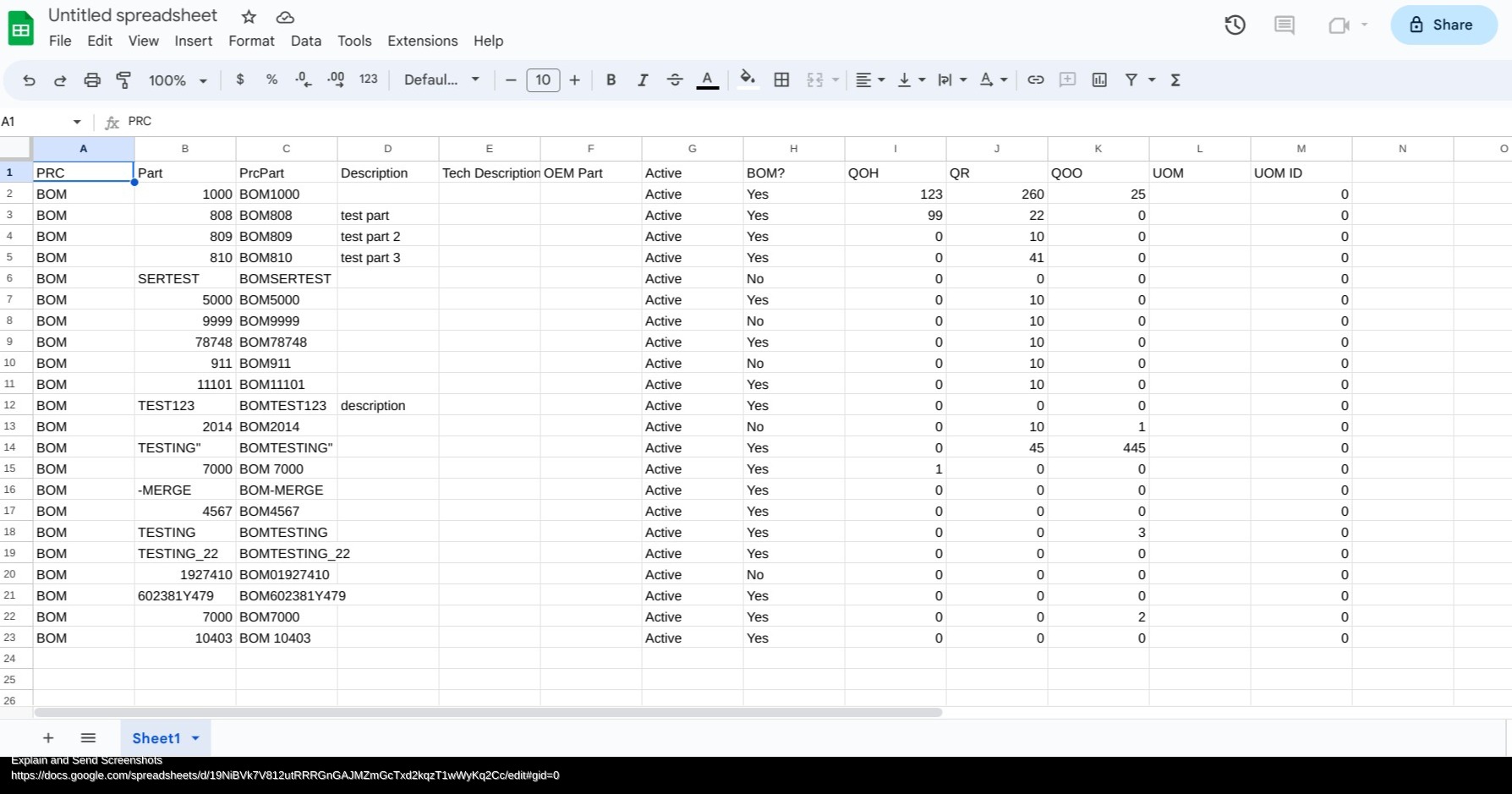

Most start-ups begin with Excel spreadsheets and Quickbooks, or some system of Quickbooks plugins and add-ons. On the financial side, Quickbooks is user-friendly and cost-effective. Spreadsheets are cheap, customizable, fast, and familiar; many people feel at home in Excel. This combo of flexibility and frugality makes this a very viable starting point for a new or small company in the 5-20 employee range.

With low transactional volume, this is a great solution. But it does not scale well, and is not capable of handling significant growth or meeting compliance requirements such as AS9100, ISO 9001, or ISO 13485. This limits the business opportunities for a small manufacturing company trying to grow.

There are some Excel wizards capable of replicating an ERP in spreadsheets, but they are few and far between. As transactions increase, inventory is more difficult to control, and orders start getting lost or delayed. Departments increasingly become isolated from each other. This results in manual data entry in different spreadsheets as each employee attempts to corral their corner of the business. Consider purchasing having to physically maintain on hand inventory to know what to buy, or getting stuck in a ‘buy per job’ practice that is not cash flow effective.

While Quickbooks and spreadsheets can be a safe, serviceable solution for a very small company, a thriving business will find itself outgrowing Excel’s capacity. Savvy business owners will begin to look for a long-term, scalable solution. At this point, we often see companies start to adopt heavily customized solutions.

Legacy ERP systems

The second option we run into are legacy ERP systems, built in the 90s. These are often on the tail-end of being supported. They are accessed through a black-screen, sometimes with a web-interface or a GUI. Typically, their customers are companies that have been using this system for many years and decades. These company’s processes and culture are entrenched in their legacy ERP.

At their best, these systems run smoothly for companies. Their employees are comfortable with their day to day interaction with the system. The risk becomes running outdated, antiquated technology that can’t readily adapt to a rapidly changing landscape. (Think: Industry 4.0.) But as long as they are stable and predictable, there is not much reason to switch.

At their worst, these systems are unpredictable and crash regularly. Employees end up leveraging offline spreadsheets to work around consistent issues. Support is expensive, if it’s even a system that is still supported at all. This represents a business critical reason to actively look into switching systems.

Home-grown systems

Home-grown systems represent the entrepreneurial, innovative side of SMB businesses. A company builds a custom system from scratch, employing either a 3rd party consultant, or their own software development team. Everything about the custom platform’s operation is custom to that company, and usually is integrated into their MES or other softwares in the ecosystem. Similar in nature to legacy systems, these are built to support that company’s needs and processes at the time of their commissioning. This can mean that as the company scales up, the limits of their home-grown system are holding them back.

There are initial benefits when building a customized system. If the system is stable and running smoothly, it’s exactly what that company wants. The system was built to their specs and vision of how their ERP system should function, meaning there is no compromising or collaborating with an external company. There is great pride in the development and innovation across the company. In fact, many web-based ERPs that we discuss later actually started their lives as home-grown ERP systems.

However, these systems come with a significant risk. Aside from the danger of software bugs, there is also a high cost to maintain or expand these systems. Expansion is a natural need, whether development needs to address fresh problems or address opportunities that the system can not already handle, such as a need for increase in inventory traceability in order to meet requirements for a highly regulated industry the company would like to target. Homegrown systems are very difficult to scale with growth, and the ‘soft costs’ must be considered as both a financial and an opportunity expense.

Databases and App-based platforms

There are a number of similarities between databases like Filemaker Pro (Claris) or an Access database and App-based platforms like Odoo. Sometimes these are platforms supported and maintained by an actual software provider, so there’s a level of stability that can be found. That is often not the case. These databases are not specifically built for manufacturing and are reliant upon a consultant or internal resources to bootstrap the platform for the specific needs and processes of an SMB manufacturer.

The risk of pursuing the database route is instability. We have heard a number of horror stories of systems crashing at month-end, or when bonuses are due. Management teams have lost sleep while a consultant spends the weekend trying to patch together a fix to maintain business operations.

App-based platforms tend to be more cost-friendly purely from the hosting side. They can be easier to start out with, since a company typically only needs one or two modules. Unfortunately, that very simplicity is also their biggest drawback. App-based platforms have limited ability to support the depth of functionality that a contract manufacturer requires. You end up back to using offline spreadsheets or cheap workarounds to piece together a solution to a problem.

These last few sections have outlined a number of options requiring heavy customization and carrying heavy risks. The last category of ERPs that we will cover provides a different option to leverage, for a more standardized, out-of-the-box solution.

Web-based, manufacturing-oriented ERPs

The last primary category of ERP solutions for manufacturers are web-based, manufacturing-oriented ERPs. A true web-native platform is built on modern technology, making it more nimble than the monolithic ERPs. Web-native ERPs provide a less bloated solution while still being enterprise-caliber and capable of supporting the critical operational and financial departments of your business.

These tend to be out-of-the-box, with less focus on customization and more on configuration and process consulting. This is due to manufacturing-oriented ERPs’ focus on a ‘best practice’ approach to development. They have more breadth and depth specific to manufacturing, with enough flexibility to adapt to multiple industries or provide a path for a wide range of niche problems per industry or company. This means cost and time to successful implementation is lower, minimizing risk and exposure during the transition.

Manufacturing-oriented, web-based ERPs represent some need to adapt a few thought processes with employees. Although many team members are flexible enough to see the value in “working smarter, not harder”, some people are hesitant to give up a familiar method for a faster one. A balance should be struck between solving the critical problems without risking or disrupting tested processes put in place for effective customer service.

When determining whether an ERP solution makes the cut as a potential solution, there are several important points to consider:

-

Technology - What is truly under the hood? Be careful of outdated platforms masquerading under a well-done web interface. What is the release cycle? How often do they release new features and bug fixes? How do they approach new development?

-

Functionality - Is this ERP truly built for manufacturing? Does this ERP understand the easiest path for processing a new order through to shipment? What’s the processes for ‘exception management’? Most of these ERPs can handle 80-90% of the business (or more) but the last 10-20% is the most critical and where these ERPs differentiate.

-

Scalability - The ERP may address the immediate problem, but there is immense risk and cost associated with being stuck in an ERP that can’t support long-term growth or new business opportunities. An ERP that can provide and demonstrate a path for growth without expensive developments, upgrades, or unending modules has a clear vision for how companies can efficiently and pragmatically grow.

-

Customer support and involvement - Is the ERP involved directly with their customers or is the customer-facing interaction left up to only VARs and third party consultants? How does the ERP field development requests and address potential software gaps? This ties in with the release cycle, but you should understand their connection to customers and speed to providing solutions to business critical processes. If working with a VAR or third party consultant, you should understand the relationship between the ERP provider and your point of contact.

-

Implementation path - two keys here are having an adaptable plan for implementation based on a proven successful strategy, and understanding the relationship between sales and the customer success/implementation team. How connected are these two? How much is the sales rep on the hook to deliver on the promises they have made while selling to you? The sales rep should be able to effectively bridge that connection with a consultant (or project manager) during the sales cycle, or demonstrate deep understanding of the complexity of an ERP implementation and your business.

Conclusion

There are hundreds of options for SMB manufacturers to consider in how to run their business efficiently, pragmatically solve problems, and competitively position themselves for success within a crowded market. ERPs are critical to this process and the foundation to the future of manufacturing - consider Industry 4.0 and the necessity of accurate, reliable data tracked and maintained easily and efficiently. SMB manufacturers must perform the cost benefit analysis of current systems and processes, and prepare their businesses for the coming wave of technological innovation.