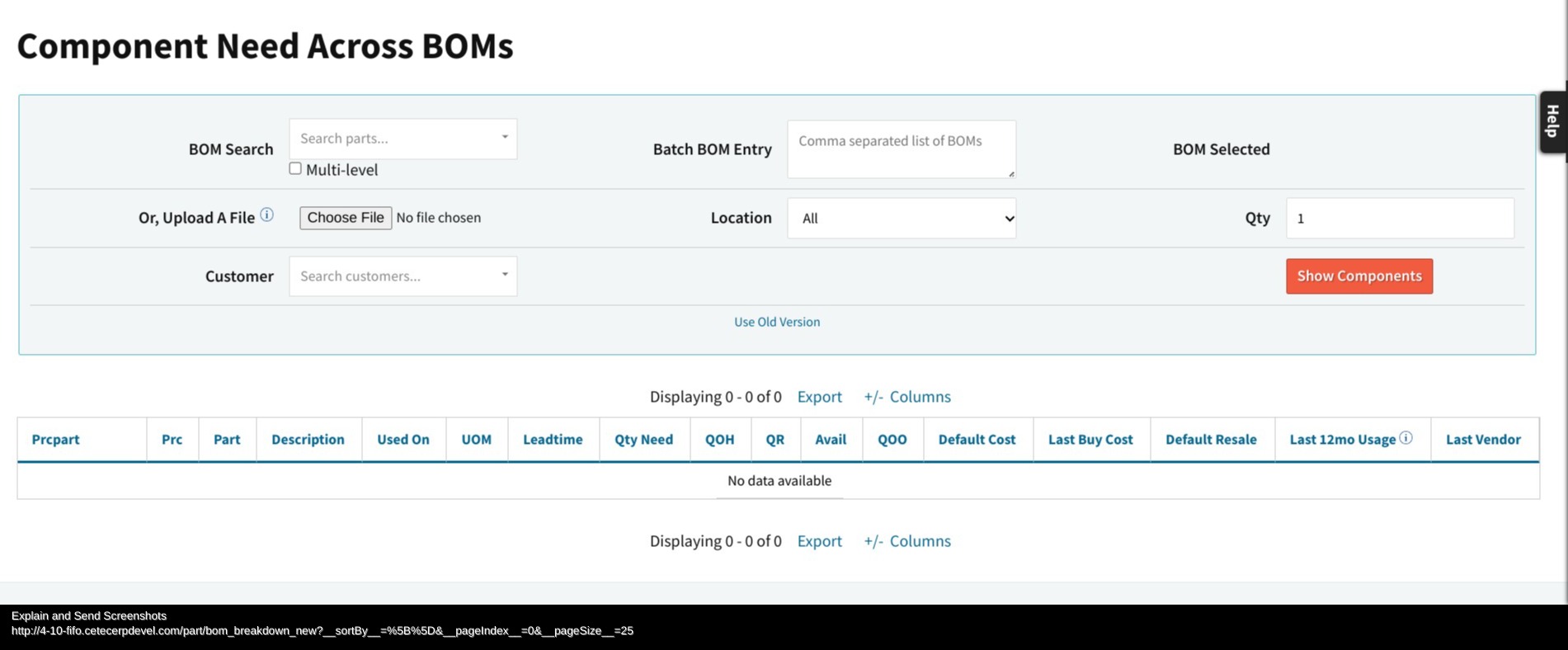

How to See Consolidated Components Across Multiple BOMs

One of the more useful reports in Cetec ERP is the Component Need Across BOMs report. This report shows a common list of parts required for multiple BOM items at one time. Seeing quantity and cost for components, consolidated across a list of different BOMs with different quantities, helps to plan and purchase for large projects. This is useful for many tasks: quoting, material planning/supply chain management, and engineering.

A number of ETO (engineer-to-order) and MTO (make-to-order) manufacturers use this data to forecast raw material needs for a large project or to help quote a large job (customer PO). ETO and MTO manufacturers have a lot of common problems. They both need to see quantity and cost for components, spotcheck for BOM accuracy by reviewing a snapshot of materials for the BOMs, and quote new contract prices for customer POs.

All these problems are solved with the Component Need Across BOMs report. You can list your BOMs manually to run the report; if you have an Excel spreadsheet of these BOMs along with the quantity of each BOM you want to build, you can import into the report. This allows you to use varying quantities of BOMs, and accurately shows the qty need of each of the components, consolidated to one row in the report.

One way to build this excel file is to use the Order list or Production Order list for a specific order or group of orders. Export the part numbers and quantities, then turn around and import your xlsx into Component Need Across BOMs report. This gives you a quick snapshot of material needs and costs for that job or project, or even portion of the project.

Cetec ERP’s Component Need Across BOMs report makes life easier for both your Purchasing department and your Sales team. When forecasting jobs, you now have an overview of what you have in stock already and what you would need to order. To learn more about this report click here.