Choosing the Right Machine Shop Management Software: What to Look For in General ERP Tools

Machine shops operate with variability, custom jobs, and constant scheduling adjustments. These shops don’t need general ERP software—they need systems that understand how a high-mix, low-volume environment actually works. Off-the-shelf platforms often miss critical functionality for quoting, tracking, and producing real jobs. Here’s what to look for in ERP tools that support the way machine shops work.

The Core Needs of Machine & Job Shops

Unlike high-volume production operations, job shops deal with one-off builds, variable customer demands, and custom workflows. No two jobs are the same, and production planning must adjust daily based on material availability, labor, and machine capacity.

Quoting must reflect actual labor and material costs. Scheduling tools need to accommodate unexpected change orders or new urgent builds. Material needs vary per job, and traceability is non-negotiable. Generic ERP tools built for retail or distribution don’t address these realities.

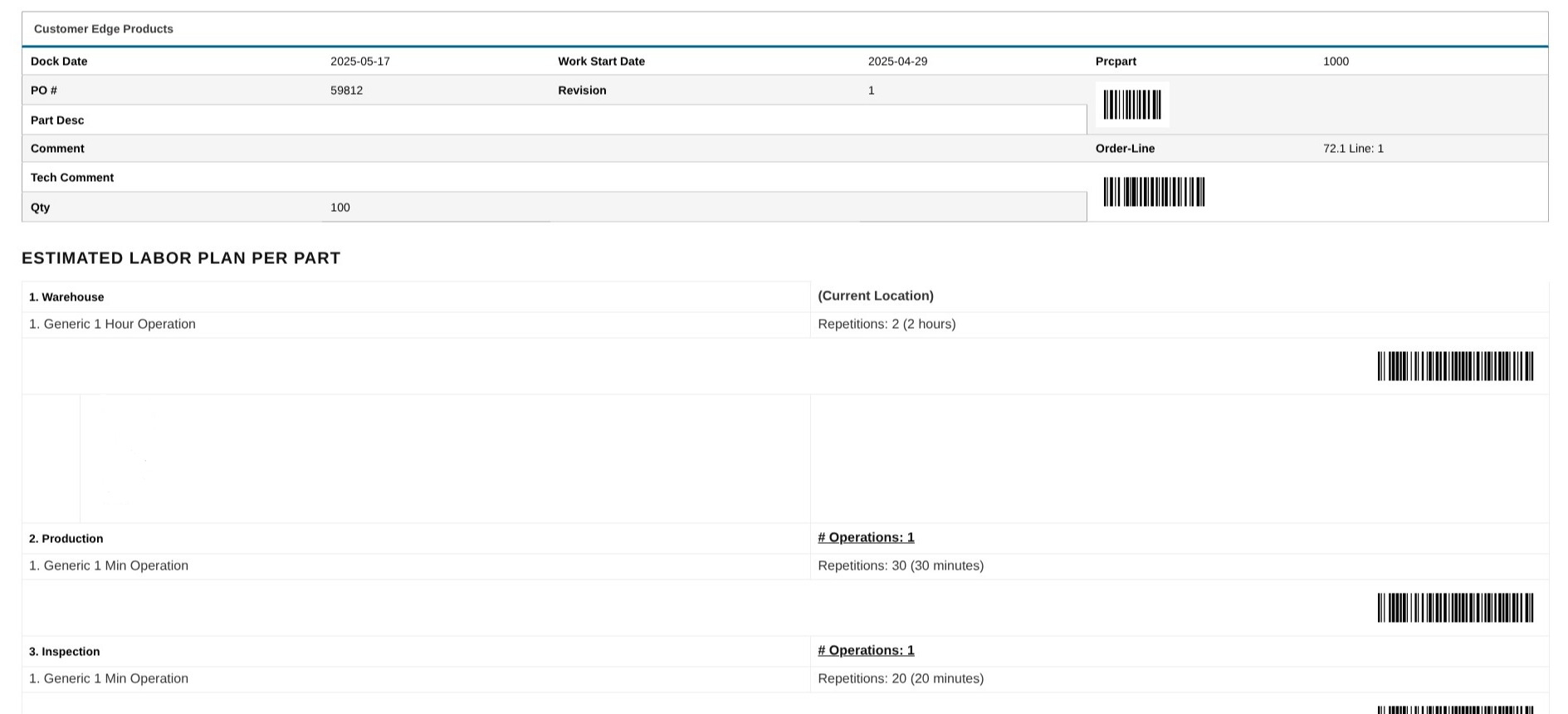

ERP for job shops should allow you to build jobs from scratch, support flexible BOMs, and tie routing and materials directly to the work order. Without these capabilities, you’ll spend more time managing spreadsheets than producing parts.

Job Tracking Must Go Beyond Status

“Job tracking” in a job shop means more than seeing if a work order is open or closed. Real job tracking includes:

- Actual labor time logged per operation

- Materials picked and issued per order

- In-process work status and location

- Operator activity and shop floor timestamps

- Routing steps and notes

- Change history, including revision-level updates

If your ERP doesn’t track all these details in real time, it becomes hard to manage capacity, check job health, or understand where margins are slipping. Surface-level job tracking creates blind spots. Real-time shop floor visibility is essential for quality, cost control, and delivery.

The ERP Features That Actually Matter

For machine and job shops, here are the features that directly impact performance:

- BOM control – Manage multi-level BOMs with revision history and real-time updates.

- Job quoting tied to job costing – Build quotes using estimated labor and materials, then track actuals for margin visibility.

- Integrated MRP and purchasing – Align job demand with part availability and vendor lead times.

- Work order tracking – See status, progress, labor, and materials in one place.

- Barcode-based inventory – Pull parts by scanning, not guessing, to improve accuracy.

- Real-time shop floor visibility – Know what’s happening on every job, across every station.

Generic systems may offer some of these features—but without the manufacturing context, they’re harder to use and easier to outgrow.

Questions to Ask ERP Vendors

When evaluating ERP systems for your shop, go beyond the demo. Ask these specific questions:

- Can the system automatically track per-job actual costs?

- How does it handle revision control on BOMs and routers?

- Are labor and material costs recorded live to the job?

- Can I adjust routing mid-job without losing audit history?

- Is purchasing tied to actual job requirements or done manually?

These questions uncover whether a system is built for job shop realities—or just adapted to look that way.

Key Takeaways

- Job shops need tools built for unpredictability and variation

- “Job tracking” must include labor, material, routing, and cost

- Generic ERP often lacks the manufacturing focus shops require

- Ask vendors specific, job shop-relevant questions

Managing a job shop requires flexible tools built for high variability and exact traceability. The right ERP system can feel like a tool designed for your floor - because it tracks what you actually do, from quote to shipment. Cetec ERP gives job shops the control and visibility needed to stay competitive. Cetec ERP is built for manufacturers - including high-mix, low-volume job shops. Explore the platform or schedule a walkthrough today.