Short Per Shelf vs Short Per Allocation

What is the difference between Short Per Shelf and Short Per Allocation?

These Short columns are visible on both the Release to Production report and the Production Order list (if the ‘Show Proj Mgmt?’ checkbox is marked when running the report).

Short Per Shelf

“The Short Per Shelf” value looks only at the current total shelf quantity against the demand from the order line being viewed. If the shelf quantity is less than the demand for the specific order line, it is considered short. Shelf quantity equals QOH minus picked quantity.

Short Per Allocation

The “Short Per Allocation” looks at all workorder demand against quantity on hand and considers work order start dates to make a prediction on if you will have enough quantity to meet demand.

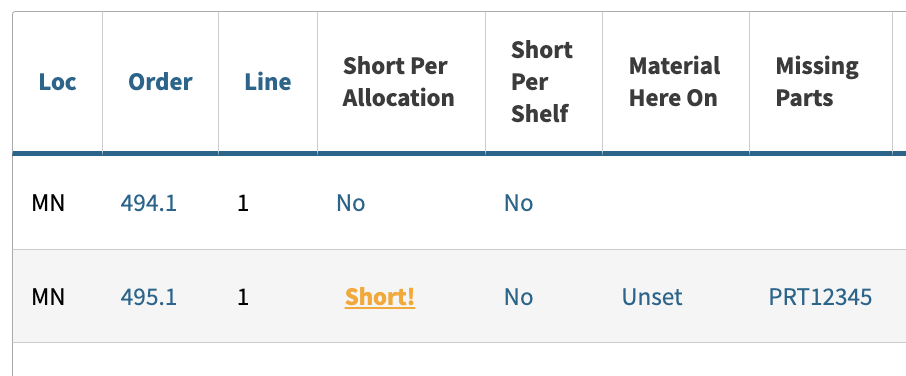

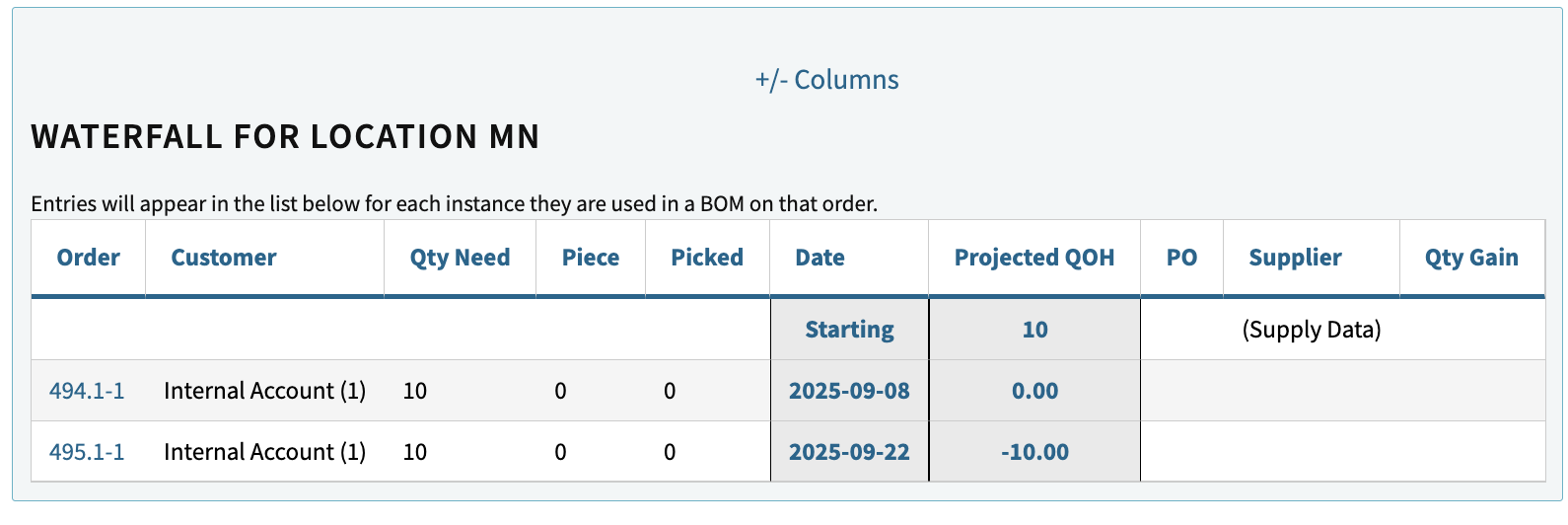

Example: Production Order List vs Parts Waterfall

If we look at the below screenshot of the Production Order list, there are 2 order lines to build top level part BOM 56789. Both lines require 10 of component PRT12345 and have different work start dates. Notice that neither order is ‘Short Per Shelf’, but only the second order which starts later is Short Per Allocation. Neither order is Short Per Shelf because the shelf quantity for PRT 920293 (10) meets the demand for each order (10). It’s important to note that this is not total demand for both orders, but individually.

Now if we look at the waterfall page for component PRT12345, we have a starting qty of 10. There is a sufficient amount for order 494.1 which will consume all 10. The second order 494.1 is considered Short Per Allocation, as the projected on hand quantity has been depleted by the previous order.

Why It Matters

Making the distinction between simple shelf qty for a part versus allocation data can be helpful in preventing shortages that are projected to occur. Inversely, knowing that you have sufficient quantity on the shelf can help you quickly fill the material needed for a specific order that may take priority.