Auto-Serialize Parts Upon Receipt

Serialization is an incredibly important factor in processing for an innumerable amount of manufacturers. The reason is that serializing parts enables accurate product identification and traceability from cradle to grave, from receipt through every step in the production process and beyond to the customer.

PRODUCT TRACEABILITY IS ESSENTIAL

One of the biggest impediments to establishing an astute materials traceability system is manual processing. Upon receiving raw materials, you may have to apply barcode stickers to thousands of raw parts. To then enter those individual serial numbers by hand into your system would be disruptive to any notion of efficiency and effectiveness in your business goals. Fortunately, Cetec ERP takes care of this problem for those in the medical device, aerospace and defense, and any other communities who rely heavily on a traceability chain.

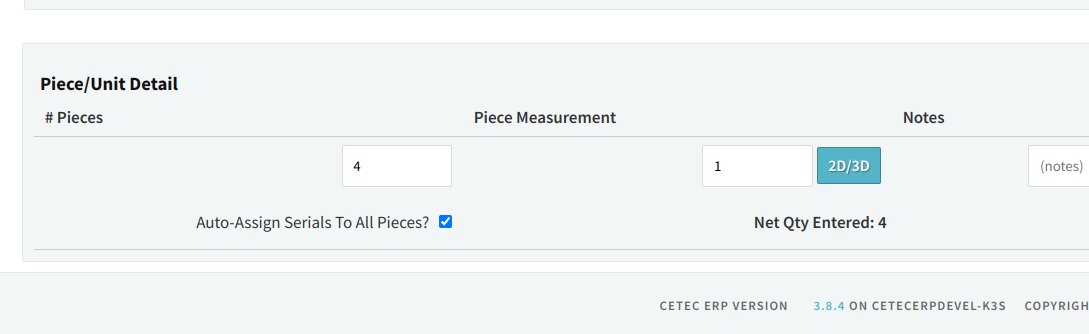

Cetec ERP users can set up personalized lot and serial code formats in their system preferences that will then translate to real-time receipt of goods. When receiving goods you wish to be serialized, you can select the option to ‘Auto-Assign Serials To All Pieces?’. Once these parts’ unit measurements and quantities have been defined, and inspections performed, serial numbers will be applied upon receipt and according to the serial scheme set out in your data maintenance table.

Choose to auto-serialize parts upon receipt. Specify number of units and unit measurement.

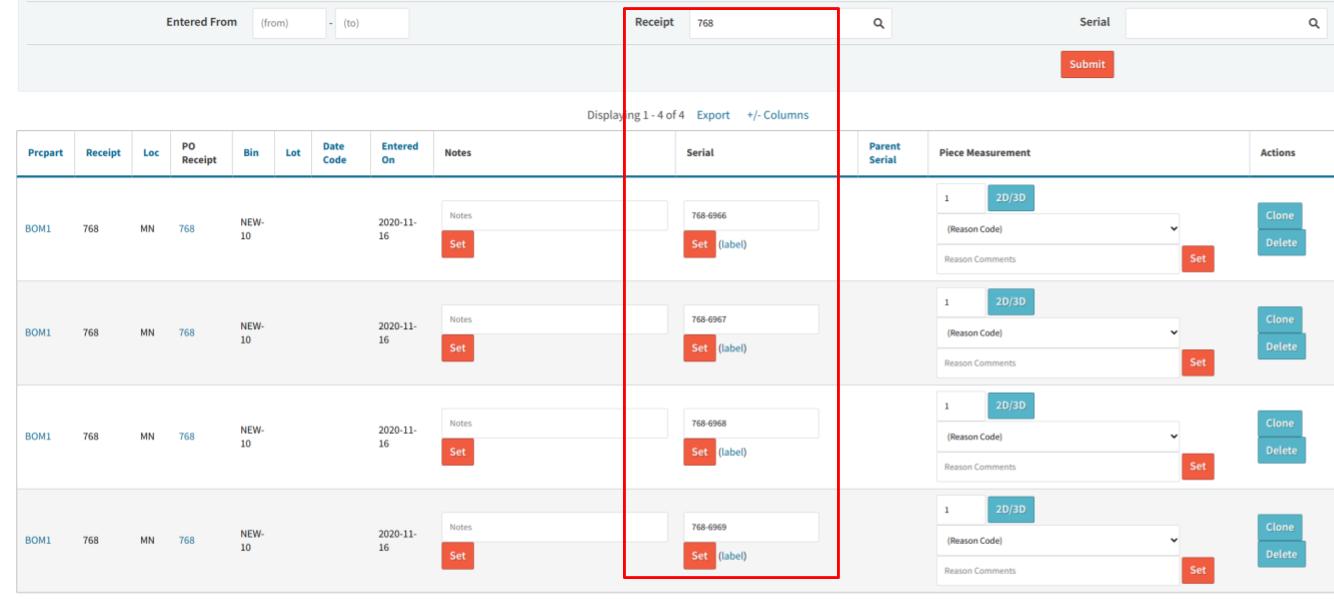

Parts with serial numbers shown on receipt report.

When you visit the receipt, you can view the serialized parts and other receipt specs; no time-consuming manual entry and no mistakes or duplicates in serial numbers.

Cetec ERP bolsters your product identification and traceability capacity with the option to auto-serialize parts upon receipt. Those in the medical device, aerospace & defense, and any other community who desire to ensure traceability of goods will find this a useful tool!