Mastering BOM Revisions: Best Practices for Effective Project Management in ETO Manufacturing

In the dynamic world of project-based Engineer-to-Order (ETO) manufacturing, managing your Bill of Materials (BOM) revisions is essential for navigating the evolving requirements of your projects. Cetec ERP provides all the tools you need for effective BOM comparison and management.

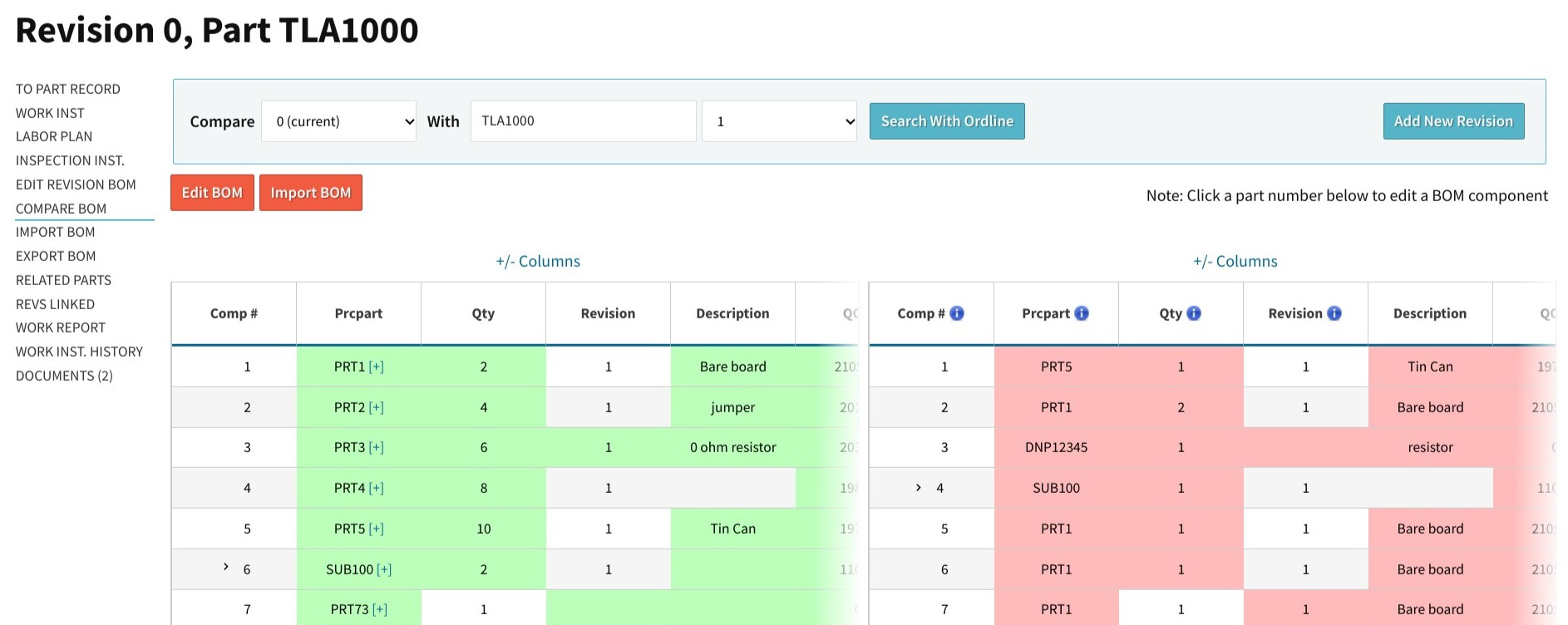

1. Understanding the BOM Compare screen

The BOM Compare screen is a feature designed to track and manage changes between different iterations of a BOM. It’s invaluable for engineering teams who need to keep up with revisions throughout a project’s lifecycle.

Utilize BOM Compare tools to efficiently monitor differences between BOM revisions. This helps maintain clarity and accuracy, ensuring that all changes are tracked and incorporated effectively.

2. Navigating BOM Revisions

When a project is secured, engineering starts with the initial BOM iteration (Rev 1). As feedback is received from the customer, updates lead to new revisions (e.g., Rev 2).

Regularly update and compare BOM revisions to reflect customer feedback and project changes. Use visual tools to highlight differences between versions, which streamlines the revision process and minimizes errors.

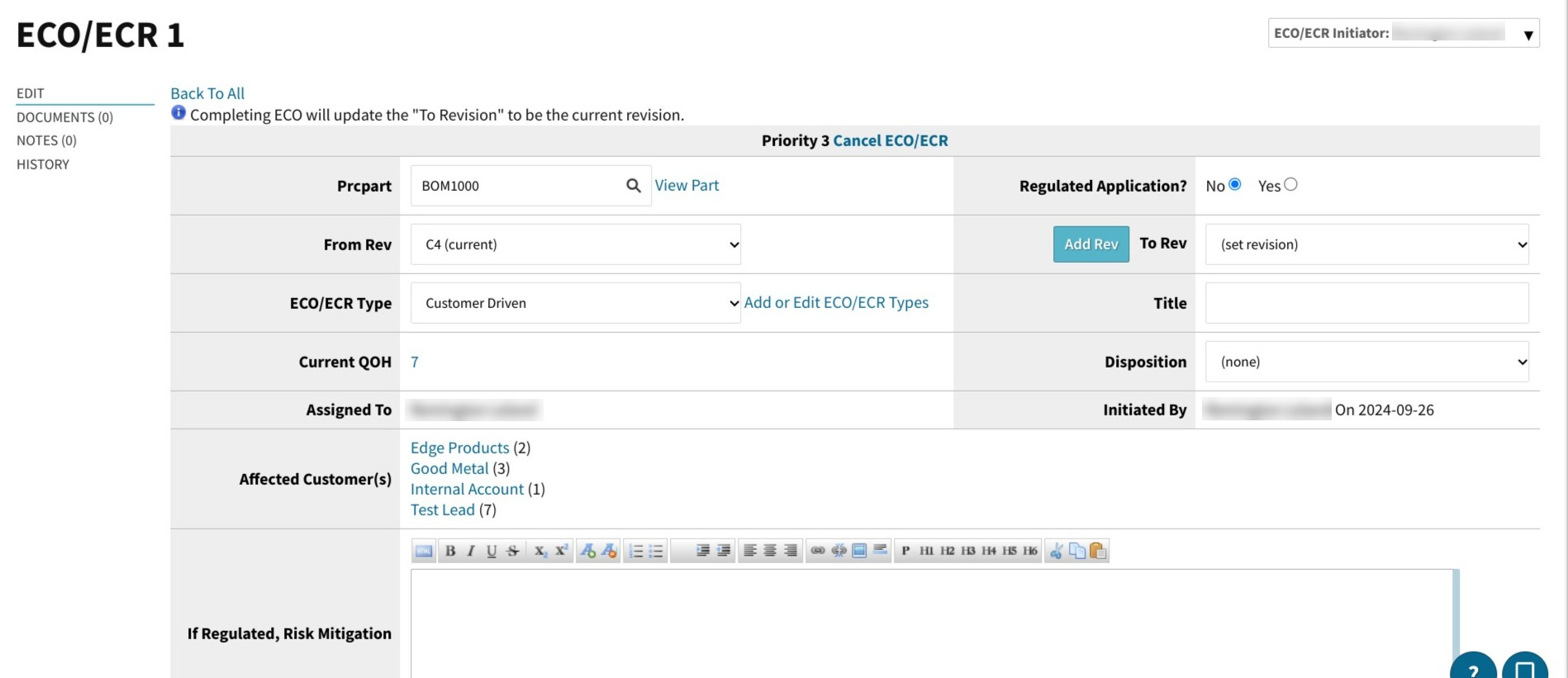

3. Managing Changes with Engineering Change Orders (ECOs)

The BOM Compare screen allows engineers to make changes and push updates between revisions. Engineering Change Orders (ECOs) document and manage these modifications.

Leverage ECOs to systematically track and communicate changes. This ensures that all modifications are properly recorded and integrated into the workflow, enhancing accuracy and communication.

4. Streamlining the Engineering-to-Purchasing Workflow

The Transition: Once the BOM is finalized, it is handed over to purchasing for sourcing materials, particularly those with long lead times.

Ensure that purchasing teams receive the most current BOM revision and understand its requirements. This approach helps in placing accurate orders and managing inventory, preventing delays and inefficiencies.

6. Managing a Fluid BOM in Project-Based ETO Manufacturing

Dynamic BOM Management: In ETO manufacturing, the BOM is not static; it evolves with the project’s requirements. This flexibility is crucial for adapting to changes in client needs and design specifications.

Early BOM Release: Releasing the BOM early allows for the early sourcing of long-lead items and can lead to better pricing. This proactive approach helps in avoiding delays and securing materials at optimal costs.

Handling Changes: Adjust the BOM and procurement orders based on client requests and design changes. This adaptability ensures that the project remains aligned with client expectations and can accommodate evolving requirements.

Tools and Techniques:

- Workflow Management: Systematic BOM release helps in timely procurement and ensures that materials are ordered and received as needed.

- Reverse MRP: Use reverse MRP to predict and manage inventory needs in light of changing BOMs. This tool helps in adjusting inventory levels and managing materials effectively. Visit our blog here.

- Shortage Reporting: Implement shortage reporting to alert procurement teams about any discrepancies or excess parts. This allows for timely adjustments to orders and helps in managing inventory efficiently.

Cetec ERP Integration: Cetec ERP integrates workflow management and reverse MRP tools to maintain adaptability. These features streamline communication between engineering and purchasing, ensuring efficient handling of evolving project requirements. Learn more.

8. Embracing Continuous Improvement

Ongoing Practice: Constantly review and refine your BOM management practices and tools to stay aligned with project needs and enhance accuracy.

Best Practice: Engage in periodic evaluations of your BOM management processes. Incorporate feedback from engineering, purchasing, and other stakeholders to improve efficiency and ensure your practices adapt to evolving project requirements.

By adopting these best practices, you can effectively manage BOM revisions, streamline workflows, and handle project requirements more efficiently. Cetec ERP’s tools are designed to support you throughout the project lifecycle, ensuring that you stay on top of changes and maintain project accuracy.